Terabase Energy Completes First Commercial Deployment of Terafab™ Solar Construction Automation System

The benefits demonstrated by this project underscore the transformative potential of automation in advancing solar construction practices, enabling us to accelerate and de-risk our project pipeline

How Robotics Can Help Global Renewable Energy Goals & Create Jobs

By buffering the dangerous aspects of solar module maneuvering and installation, these smart robotic arms are creating processes to move solar equipment faster and build sites with fewer errors.

How Can the Utilities Industry Benefit from Robotics?

For the utility industry, these new robotics could offer significant benefits - and, in some cases, we're already beginning to see how the adoption of robots can make utility work safer and more productive.

3 Trends in Robotics Energy Consumption

Energy efficiency is an increasingly prominent concern as electronics adoption and environmental consciousness both rise. Robotics must consume less energy to sustain their growth in the future.

Energy Saving in Die Casting Automation

Die casting, the process of forcing molten metal into molds, is far from new. Today, casting processes use a lot more advanced technology, specifically robots, than in years past. These 'bots have many advantages in die casting, but energy saving is one of the most substantial.

Robotic Assistance and the Future of Energy Sustainability

We already know that robotics can help protect our oceans in a number of ways, from improving wastewater treatment to improving fuel efficiency on ships. Thus, it makes sense that robotic assistance can have a positive impact on the sustainable energy sector.

Records 1 to 6 of 6

Featured Product

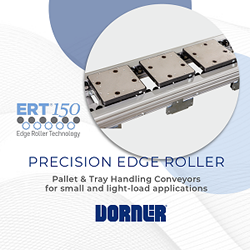

The ERT150 - Dorner's Next Evolution of Edge Roller Technology Conveyors

The next evolution in Dorner's Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating means Dorner's ERT150 will conform and not contribute to the contamination of cleanrooms to those standards. As implied by its name, the ERT150 (Edge Roller Technology) uses rollers to move pallets through the conveyor smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT150 is suited to operate in cleanroom environments requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including medical devices, electronics, consumer goods among others.

.jpg)